By Restb.ai on 2 November 2016

We use it everyday - driving our cars, heating our homes and powering our economies. OIL.

But have you ever really thought about how we access the black gold from giant underground reservoirs?

We harvest oil through enormous pipelines that access reservoirs deep beneath the earth’s surface. Kind of like giant straws pulling the oil up to rigs that can process the crude material and make it suitable for distribution and consumption.

THE PROBLEM

Well, in the world of oil production, there’s one nasty element that capable of causing a massive decline in production and in the process destroying billions of dollars of value. That is scale deposition.

Every oil production unit in the world battles with scale deposits and it’s unpredictable negative effect on their bottomline. Currently, the problem is faced the same way we deal with a clogged drain in our kitchen sink. The water won’t go down, we take a look, pour some chemicals down the drain, and then carry about our business. In other words, scale deposition is dealt with manually and you never really know when there’s a problem until the oil actually stops flowing.

But what if oil production teams worldwide could remove the subjective element of preventing scale deposit buildup and in the process optimize their pipelines proactively?

That’s exactly what Scale Protection had in mind when they called Restb for a deep learning solution to this global problem.

THE SOLUTION - IMAGE RECOGNITION TECHNOLOGY

The biggest issue with the current process oil companies use to resolve scale build up in their pipelines is that it varies from engineer to engineer and company to company. Everyone has their own individual process to determine when the pipeline is no longer performing adequately and the deposits must be removed via a chemical flush.

The primary objective of utilizing a deep learning image recognition solution was to standardize the process. Scale Protection, leading global experts in maintaining optimal pipelines for their clients, wants to remove the guesswork and make this entire process systematic.

Well, in order to accomplish this they would need data…a lot of data. To access the data, Scale Protection offered to run deposit buildup analysis for free for their clients as well as simulated lab experiments that would provide a large enough data set to identify patterns of the crystal makeup of the scales. Once they identified similar traits among the various types of crystal deposits, they could then nail down the most opportunistic time to flush them out with their proprietary chemical solutions, thereby maintaining a constant level of production without any unexpected disruption.

However, that still didn’t solve the problem of automating a standardized system that tells their clients exactly when and in what proportions to add more chemicals to their pipes. In essence, it was still a manual process.

Enter Restb.

“Restb’s technology has allowed Scale Protection to automatically understand and pull patterns from microscopic images taken of the crystals placed in the oil pipes,” says Restb co-founder Angel Esteban. “Our artificial intelligence acts like a chemical engineer, appreciating the quantity of certain types of chemical substances with a human-like accuracy”

THE RESULTS

Here’s a deeper look at the details of how Restb’s image recognition technology has automated and advanced the ability of oil production teams to understand how often they need to utilize Scale Protection’s solutions in order to maintain optimal conditions.

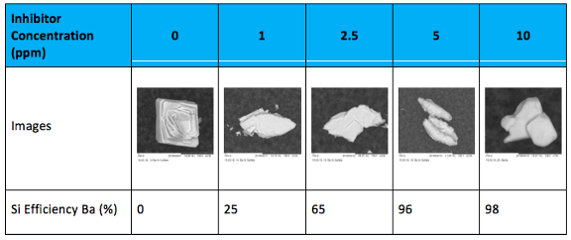

First, we produced scale in the laboratory and then took microscopic images for each of the different inhibitor concentrations. The ion concentration also made it possible to accurately calculate how effective the inhibitor was, Si Efficiency Ba. This is not possible in a real-life situation, but the test was done to see if the morphology recognition could be modeled in a way as to give a reasonable estimate of the efficiency of the inhibitor.

As you can see above, the morphology is sensitive to Scale Inhibitor concentration. However, it is seen as an uncertain exercise to base the evaluation upon a man-made (subjective) interpretation. Machine learning applications have been tested to see if more consistent evaluation can be achieved.

With the support of Restb, we trained an image recognition model using 150 images of scale crystals made without any inhibitor present and with high inhibitor, above 5 ppm. This model was then applied to 50 new images from each tested inhibitor levels.

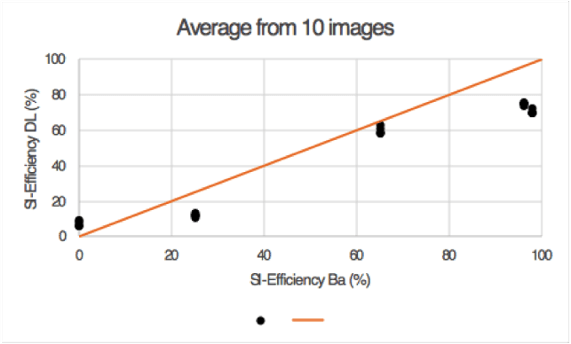

The figure below shows average numbers are calculated for each of the 50 values in each dataset. The 10 images selected in each average are randomly selected among the 50. This shows that the average Si Efficiency calculated by the Deep Learning model (SI-Efficiency DL) does correlate well with the SI-Efficiency Ba from the ion measurements.

In other words, this proves that by processing 10 images it is possible with a fair level of accuracy to know at which conditions with regards to RSI the crystals are precipitated in. Marvelous!

In conclusion, by leveraging the image recognition and deep learning abilities of Restb’s API, Scale Protection has become an innovator in their field and the first company of its kind to offer its clients the ability to know exactly when to add the chemical dissolvents to maintain optimal oil production.

Read more about Image Recognition.

comments